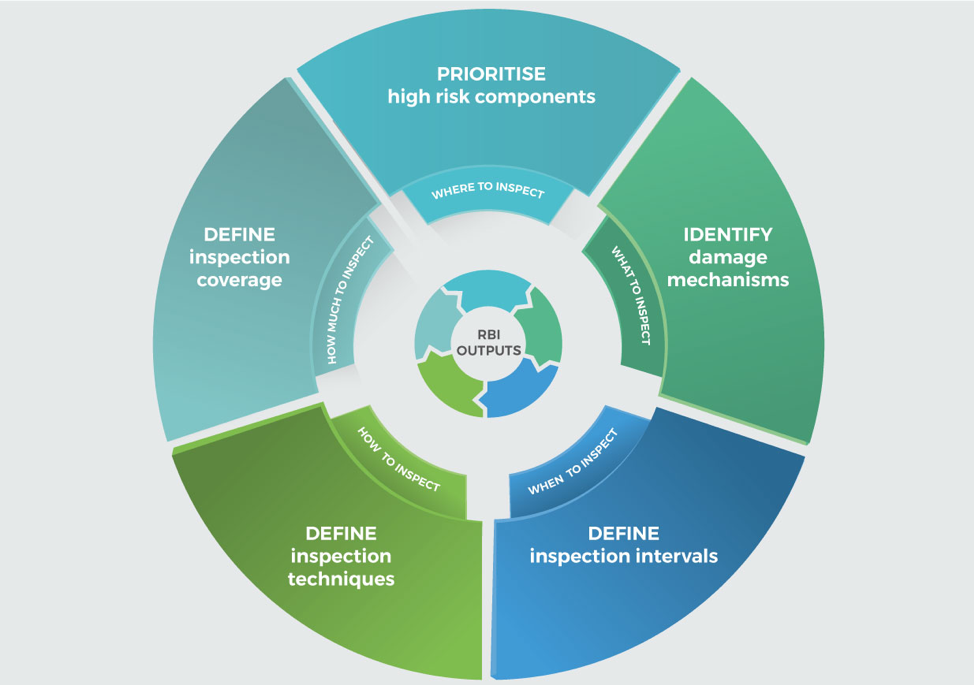

1. Risk Based Inspection (RBI)

Risk based inspection is a risk assessment and management process that is focused on the loss of containment of pressurized equipment in processing facilities, due to material deterioration. These risks are managed primarily through equipment inspection. In most processing plants, a large percent of the total unit risk will be concentrated in a relatively small percent of the equipment items. These potential high-risk components may require greater attention, perhaps through a revised inspection plan.

Saudi QTech – LifeTech’s RBI methodology can be used to manage the overall risk of a plant by focusing inspection efforts on the process equipment with the highest risk. Our RBI methodology provides the basis for making informed decisions on inspection frequency, the extent of inspection, and the most suitable type of NDT.

Benefits of Using RBI

- Meaningful risk reduction and improved plant availability and safety

- optimize the limited budget of the inspection and maintenance departments

- Extend shutdown and inspection intervals

- Optimize inspection methods and avoid over-inspection

- Legislative compliance

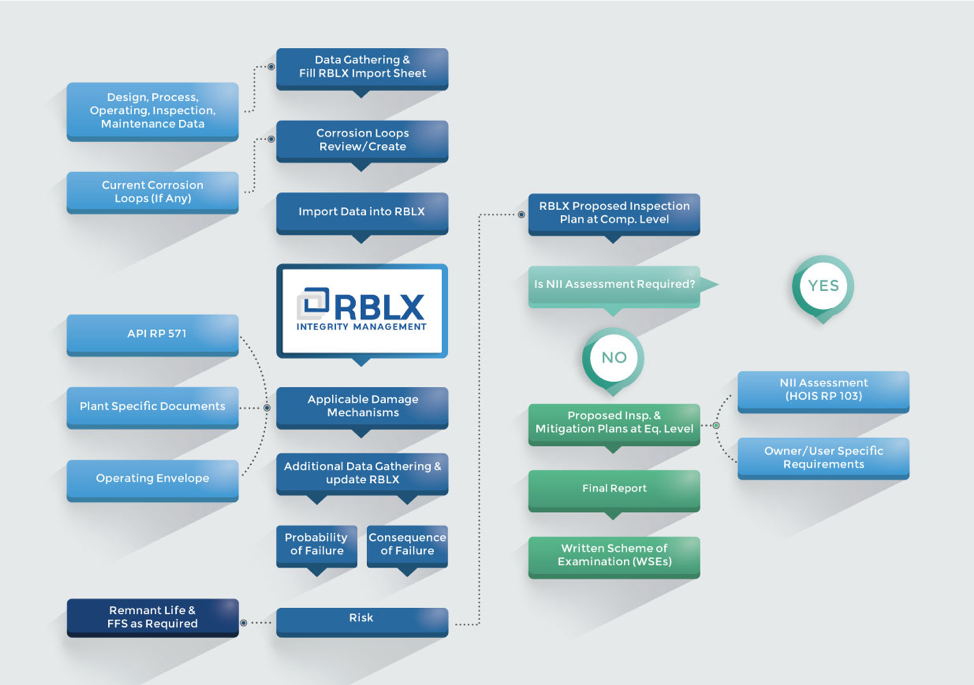

RBLXTM is a quantitative/semi-quantitative cost-effective risk based inspection software suite, developed by LifeTech Engineering, which can be used in implementing RBI, Corrosion Risk Assessment (CRA), Remaining Life Assessment, and Life Extension projects.

RBI Approach

2. ADVANCED NONDESTRUCTIVE TESTING (ANDT)

- GUIDED WAVE INSPECTION (GWI)

- GUIDED WAVE SENSORS INSTALLATION (gPIMS)

- AUTOMATED ULTRASONIC TESTING (AUT)

- PHASED ARRAY ULTRASONIC TESTING (PAUT)

- TIME OF FLIGHT DIFFRACTION (ToFD)

- TANK FLOOR INSPECTION (B-MAP)

- CORROSION UNDER INSOLATION (CUI)

- PIPE HIDDEN WALL INSPECTION (RACK-UT)

- BORESCOPE INSPECTION

3. CONVENTIONAL NONDESTRUCTIVE TESTING (CNDT)

- RADIOGRAPHY TESTING (RT)

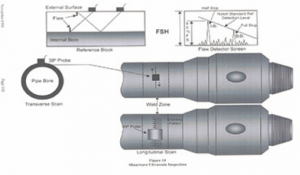

- ULTRASONIC TESTING (UT)

- MAGNETIC PARTICLE TESTING (MT)

- DYE PENTRANT TESTING (DPT)

- HARDNESS TESTING (HT)

- POSITIVE MATERIALS IDENTIFICATION (PMI)

4. LIFTING INSPECTION

Lifting Appliances

- Mobile cranes

- Portal cranes

- Overhead/gantry crane

- Self-loading arms/ HIAB

- Fixed lifting beams & Jacks

- Mobile Aerial Platforms

- Hoists

- Pad eyes (fixed structural)

- Forklifts

- Side booms

- Beam trolleys

- Sheave blocks

Lifting Accessories

- Wire rope sling and Webbing sling

- Chains and chain slings

- Shackles

- Beam- and Plate clamps

- Eye bolts & swivel rings

- Hoist rings

- Wedge sockets

- Safety harnesses

- Spreader beams

- Hooks

- Pad eyes and bolts

- Hooks.

Lifting Equipment

- Containers

- Skids

- Skips

- Drum racks

- Baskets

- Pipe racks

- Big bags.

5. RIG INSPECTION SERVICES

Rig Inspection Parts

1- Crown Block and Water Table

2- Cat line Boom and Hoist Line

3- Drilling Line

4- Monkey board

5- Traveling Block

6- Top Drive

7- Mast

8- Drill Pipe

9- Doghouse

10- Blowout Preventer

11- Water Tank

12- Electric Cable Tray

13- Engine Generator Sets

14- Fuel Tanks

15- Electric Control House

16- Mud Pump

17- Bulk Mud Components Storage

18- Mud Pits

19- Reserve Pits

20- Mud Gas Separator

21- Shale Shaker

22- Choke Manifold

23- Pipe Ramp

24- Pipe Racks

25- Accumulator

26- Annulus

27- Brake Bands

28- Casing Head

29- Cathead

30- Catwalk

31- Cellar

32- Conductor Pipe

6. TUBULAR INSPECTION

SAUDI QTECH Provides All Types Of Tubular Inspection As:

1- Drill pipes

2- BHA

3- Tubing & casing

4- Elevators & slips

5- Stabilizers and Special drilling tools

Tubular Inspection Services

Tubular Inspection includes inspection of New and Used Oil Country Tubular Goods covering Drill Pipes

• Heavy Weight Drill Pipes, Drill Collars, Casing.

• Tubing and Bottom Hole Assembly.

• Inspection Services in offer are

• Electromagnetic inspection unit – EMI for Drill Pipe Body Inspection.

• Electromagnetic inspection unit – EMI for Tubing Body Inspection.

• Electromagnetic inspection unit – EMI for Casing Body Inspection.

• Magnetic particle inspection – MPI.

• Ultrasonic Share Wave.

• Ultrasonic Thickness Gauges.

• Thread Gauging Unit.

• Straightening Machine.

• Internally Full-Length Cleaning Machine.

• Externally Full-Length Cleaning Machine.

• Break Out Bucking Machine.

• Visual Pipe Inspection.

• Dimensional Inspection of Pipe.

• Visual Thread Inspection.

• Tool Joint Dimensional Inspection.

• Dimensional Inspection of Rotary Shoulder.

• Wet fluorescent magnetic particle (black light) inspection.

• Dye Penetrant Testing API Full Length Drifting.

• Hardness Testing.